A Guide to the 7 Most Common Coating Application Methods Types

Navigating the intricate world of coating application methods is akin to mastering the art of painting on a vast, ever-changing canvas. The importance of selecting the right coating application method cannot be overstated—it directly influences the durability, efficiency, and overall success of the protective or decorative layer being applied. Each method comes with its own set of challenges and nuances, making the choice a pivotal decision in the coating process.

In this comprehensive guide, we delve deep into the diverse universe of coating application methods. From the precision of spray techniques to the versatility of dip coating, and the efficiency of brushing to the innovation of electrostatic methods, we cover the spectrum to ensure you have a complete understanding of each approach. We’ll explore the hurdles inherent to different application methods—be it the skill level required, equipment necessities, environmental considerations, or material compatibility—and provide you with the knowledge to navigate these challenges confidently.

Choosing the appropriate application method is no small feat; it requires a delicate balance of project needs, material properties, and desired outcomes. This guide offers insights into making these critical decisions, ensuring that whether you’re working on a large-scale industrial project or a delicate artistic endeavor, you have the tools needed to select the method that aligns with your objectives.

Additionally, we’ll share essential precautions and best practices to keep in mind during the application process, helping you avoid common pitfalls and achieve a flawless finish.

By the end of this journey, you will not only understand why choosing the right coating application method is crucial but also how to expertly apply these techniques to your projects. Whether you’re a seasoned professional or new to the field, this guide is designed to enrich your knowledge and empower you to make informed decisions in the complex world of coatings.

What are the types of processes for coating application methods?

Coating application methods are crucial in achieving a successful finish for any project. Understanding the types of processes available can help you choose the most suitable method for your needs. Let’s explore some common coating application methods and their unique characteristics:

- Brushing:Brushing is a traditional method of applying paint or coatings to a surface using a brush. It works well for small areas or intricate details. The key to successful application is for an experienced person to use the appropriate brush for the paint type and surface, maintain consistent brush direction, and apply the paint evenly for optimal leveling and distribution of the liquid polymer. Brushing provides good control over the thickness of the coating, but may result in visible brush marks. The brush coating process offers low waste, low cost, and economical suitability for short runs, but is relatively slow compared to other coating technologies.

- Spraying:Spraying is a versatile, economical, and fast coating process that is suitable for surfaces of different types, sizes, and shapes. Manual/automatic coating can be adopted, the transmission efficiency is high, and it is conducive to forming a large area, smooth and uniform surface. It involves the use of spray gun equipment ( such as air atomized conventional spray, airless spray, air-assisted airless spray, electrostatic spray, high volume low pressure (HVLP) and thermal spray, etc. ) to atomize the coating into tiny droplets, which are then Apply to the surface. Compared to brushing, this method is effective at covering large areas quickly and achieving an even finish. and meet individual requirements such as surface quality, required film thickness, edge build-up, reduced overspray, reliable performance, etc. However, if applied improperly, it may also cause shortcomings such as uneven spraying, sagging, orange peel, pinholes, overspray and splashing. Also due to the risk of inhalation, appropriate ventilation and protective equipment are required.

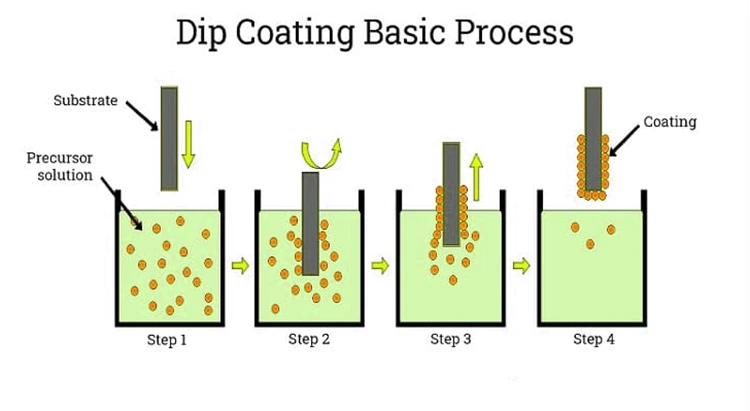

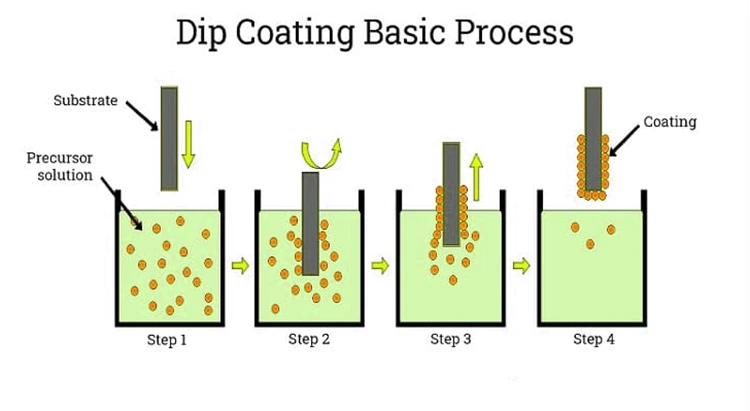

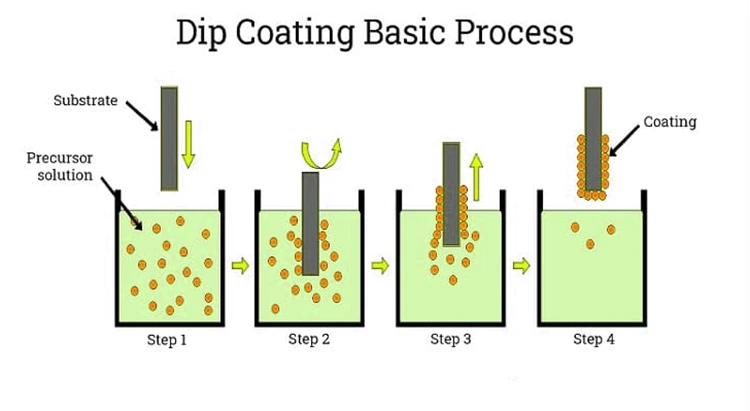

- Dipping:Dipping involves dipping an object or substrate into a tank or container containing coating material and then removing it at a constant rate under controlled temperature/atmospheric conditions. This cost-effective process is suitable for coating small, complex-shaped objects or applying a uniform coating to a large number of parts. The viscosity of the coating, the soak time, the rate of removal from the tank and the number of dip cycles determine the thickness of the coating. Impregnation ensures complete coverage of the substrate but may require additional steps such as draining and drying. It may also cause excess material to drip.

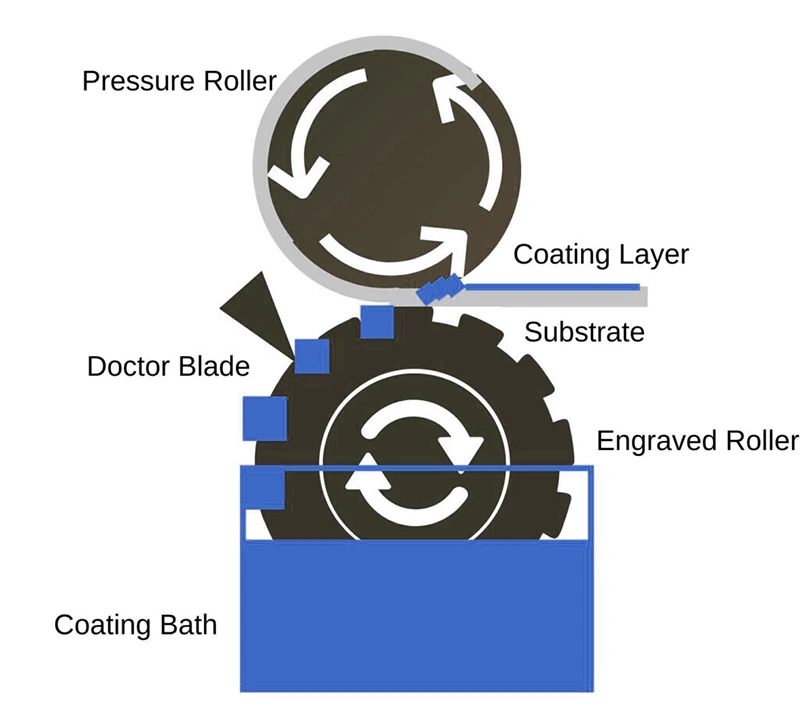

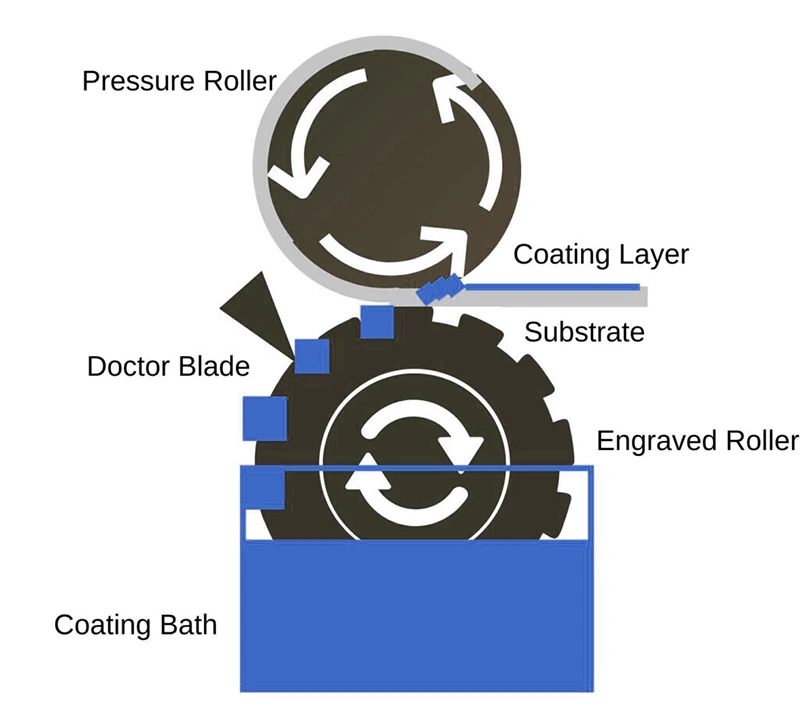

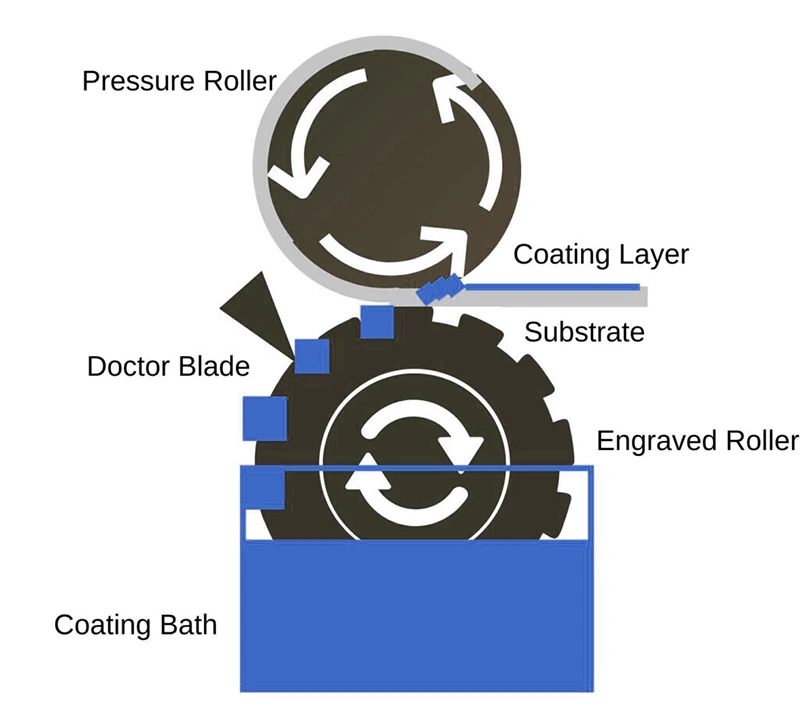

- Roller coating:Roller coating uses a paint roller to apply paint to the surface of an object. It is commonly used to apply paint to walls, floors, and other large flat or slightly curved surfaces. Using automated roller coating equipment, such as direct roller coaters and reverse roller coaters, liquid polymer coatings of uniform thickness can be applied to flat surfaces over a large area to achieve mass production. This popular continuous energy-saving process requires less labor and reduces labor waste. However, care must be taken during application to avoid roller marks and ensure proper coverage. Sometimes multiple coats may be needed for complete coverage.

Click here to learn about the working structure of different roller coating equipment types.

- Flow Coating:Flow coating is a fast, simple, and reliable manual/automatic liquid coating process. Paint can be poured onto a surface and allowed to flow and spread naturally and evenly. Paint is pumped from the paint storage tank to the upper surface of the product through hoses and nozzles, and flows up and down the sides of the product. Excess paint flows naturally into the collection tray below for recycling. This method is suitable for coating large, flat surfaces or irregularly shaped surfaces. Flow coating provides an even finish with minimal brush marks. The flow coating process is economical, minimizes waste, and has high transfer efficiency. But the flow coating process requires careful control of coating viscosity and flow rate to ensure uniform coverage, and is not friendly to parts with holes/pultrusion.

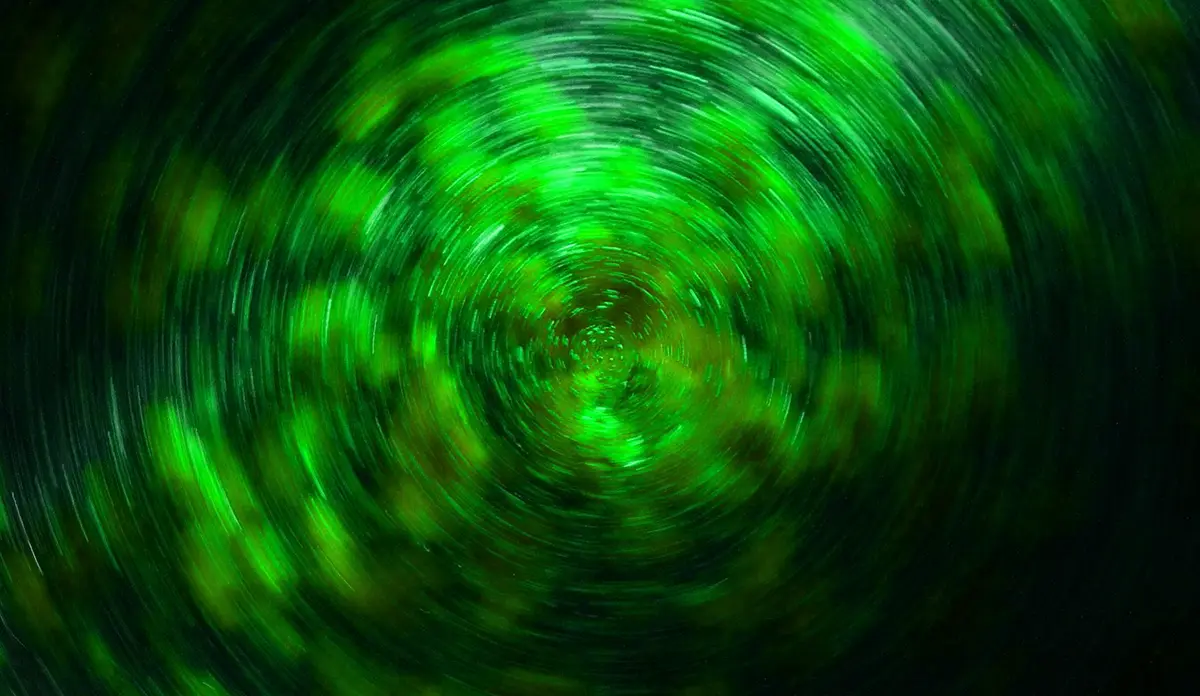

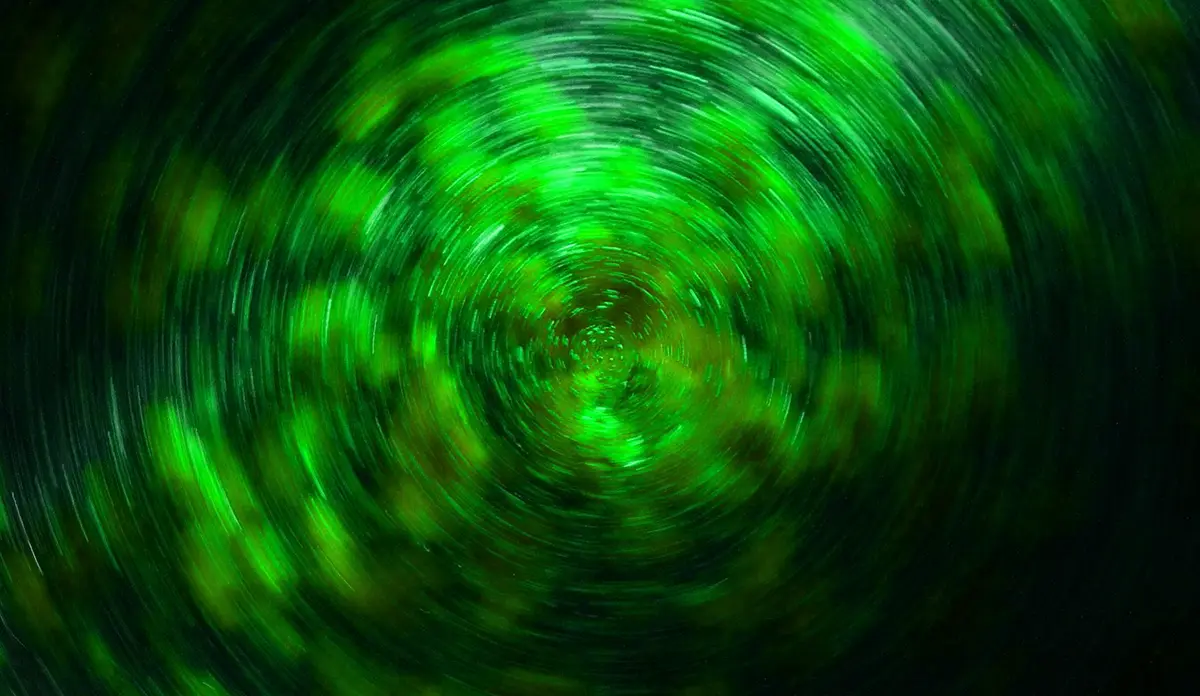

- Spin Coating:Spin coating is a method of applying a thin, uniform coating to a substrate. It works by using liquid-vapor, which places the substrate on a rotating platform and dispenses a small amount of coating material into the center of the substrate. As the platform rotates, centrifugal force causes the coating to spread and form a thin film. Spin coating is commonly used in the semiconductor industry to apply photoresist coatings. In this method, the film thickness is determined by the viscosity of the coating solution and the spinning speed.

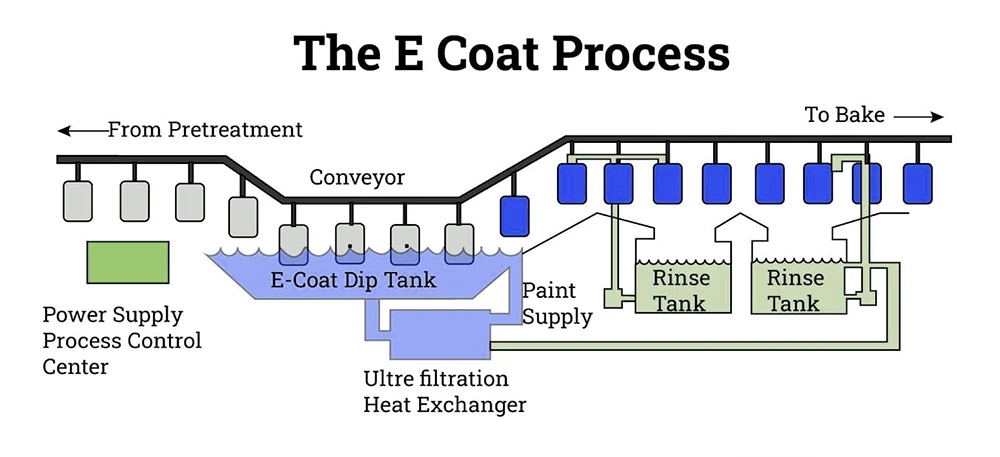

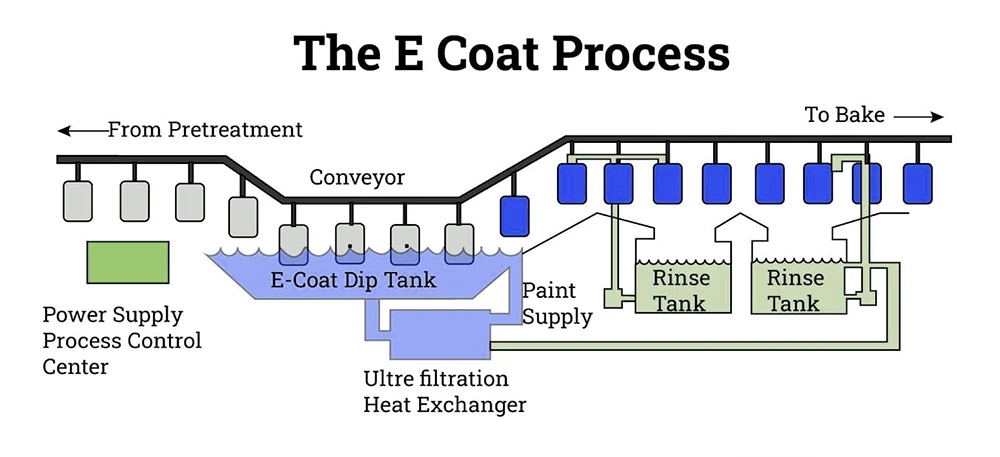

- Electrophoretic coating:Electrophoretic coating, also known as e-coating, is a dip coating process. It involves immersing the part in a bath of paint or coating material and applying an electrical current to deposit paint particles onto a conductive surface. Electrocoating provides excellent protection against corrosion and is commonly used to apply protective coatings to metal parts, for example in the automotive industry.

Each of these coating application methods has its advantages and limitations. By understanding the characteristics of each method, you can choose the most suitable one for your project. Whether you’re looking for precision, efficiency, or a specific finish, there’s a coating application method that’s right for you.

Inorganic coatings application methods.

The above are the methods for applying organic coatings & paints in daily life. There is also a large branch in the industrial field: inorganic coatings. It is fascinating to see the smooth transition from the field of organic coatings and their various application methods to the field of inorganic coatings. Inorganic coatings have unique advantages and application technologies tailored to specific needs, especially when durability and longevity are critical. If you are still unclear about the differences between organic and inorganic coatings, you can go to our corresponding blog for detailed understanding, which will not be expanded here for the time being . Let’s explore some key application methods unique to inorganic coatings and their defining characteristics:

- E-Coat (Electrophoretic Coating):E Coat is a combination of electroplating and spray painting. E-Coat deposits charged particles onto conductive surfaces, a process that allows for coating on the interior and exterior of parts. Because it provides comprehensive coverage, even on complex shapes, ensuring excellent corrosion protection and uniform thickness while minimizing waste. It is particularly valued in the automotive, oil and gas industries, HVAC systems, water and wastewater management, and aerospace industries. Suitable for a variety of metal substrates, such as: castings, stampings, structural iron, pipes, springs and aluminum castings, etc. Yes, this process is applicable to both inorganic and organic coatings.

- PVD Coating (Physical Vapor Deposition):PVD coating, also known as thin film coating, stands out for its method of vaporizing metal in a high vacuum environment and then depositing it onto the target surface. The main process methods of PVD coating are sputtering and thermal deposition. Thermal deposition uses high temperature and vacuum pressure for vaporization, while sputtering uses a high-energy vacuum chamber. PVD coating can form extremely thin, environmentally friendly pure metal or cermet coatings to enhance the appearance, durability and functionality of components.

The technology is widely used in films in tools, watches and medical devices, providing superior hardness, abrasion resistance and a variety of colors without compromising the integrity of the substrate.

- Chemical Vapor Deposition (CVD):Similar to PVD but using chemical reactions at high temperatures to deposit material, CVD coatings are acclaimed for their purity and strong bond to the substrate. This method excels in creating coatings for semiconductors, fiber optics, and aerospace components, providing excellent thermal and chemical resistance.

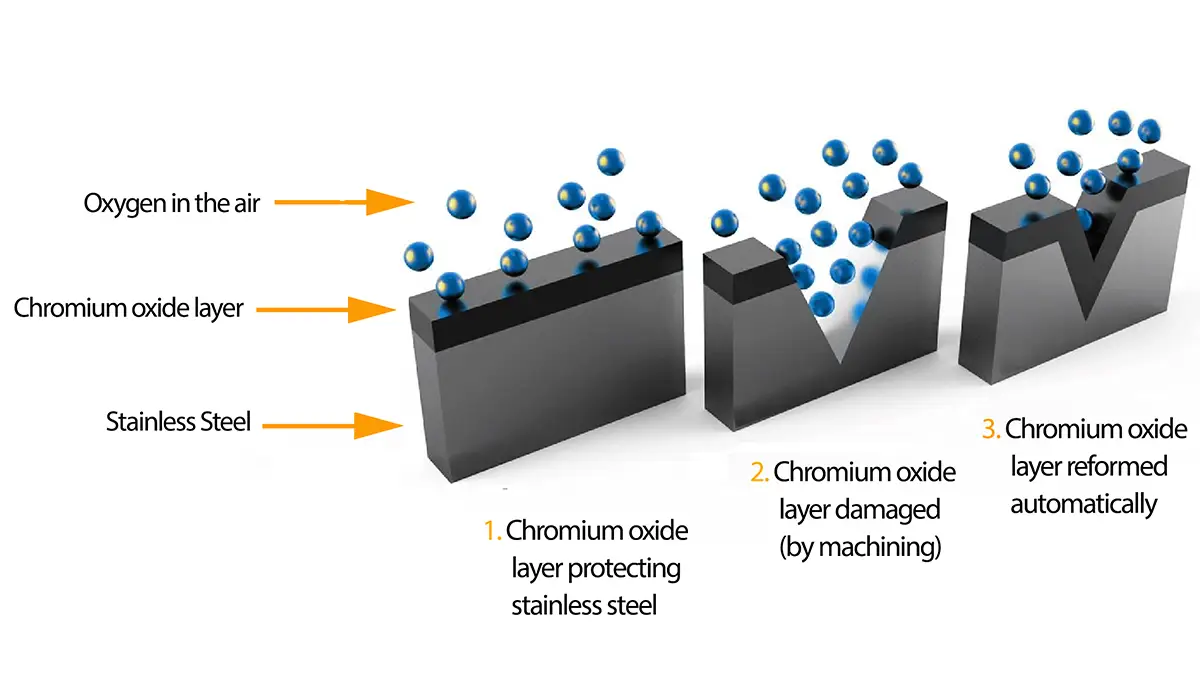

- Surface Conversion Coating Process:This method chemically converts the surface layer of the substrate to a protective layer, offering improved corrosion resistance, enhanced adhesion properties, and a base for subsequent coatings. Commonly used techniques include chromate conversion coatings for Nitriding, aluminum and phosphating for steel.

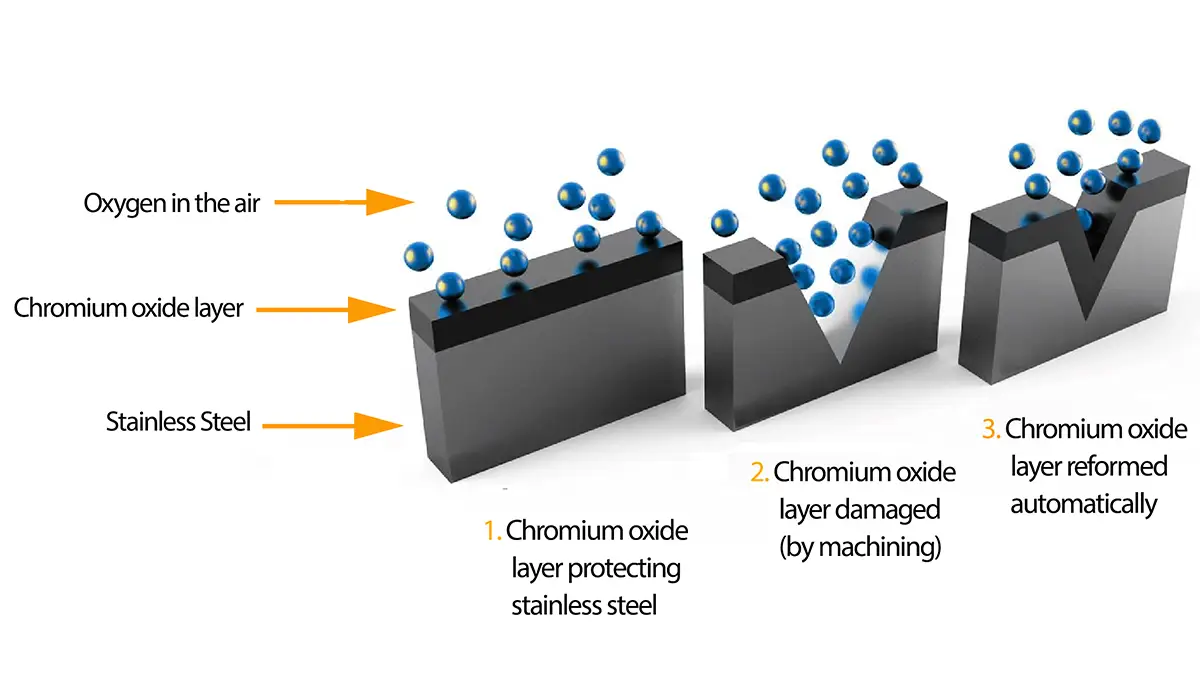

- Passivation Film:Often applied to metals like stainless steel, the passivation process involves treating the surface with a mild oxidant to create a thin, protective oxide layer. This film enhances corrosion resistance by making the surface more passive and less reactive to environmental factors.

Inorganic coating application methods bring their own set of advantages, from enhancing durability to improving resistance against harsh conditions. Whether through the precision of PVD, the protective qualities of E-Coat, or the innovative approaches of CVD, these methods ensure that surfaces not only gain an aesthetic appeal but are also equipped to withstand the test of time and environment. If you are interested in inorganic coating application methods, you can leave us a message. We will consider publishing a detailed guide to the application process of inorganic coatings based on your needs. Transitioning from organic to inorganic coatings, we see a world of possibilities where the choice of application method opens new avenues for durability, efficiency, and performance.

What Are the Technical Challenges of Coating Methods?

Navigating the intricate world of coating application methods, each with its unique technical hurdles, can be akin to guiding a ship through a stormy sea. These methods, from the traditional brush and roll to the advanced electrophoretic painting, promise to leave a mark of beauty and durability on surfaces. Yet, they demand from us a mastery over their temperamental nature and an understanding of the challenges that lie in the pre-treatment, application, and post-treatment stages.

Preprocessing challenges.

Before the first drop of paint graces a surface, pre-treatment processes must ensure that the canvas is pristine. The main challenges here include:

- Surface Preparation:Achieving the ideal surface cleanliness and roughness is crucial. Techniques such as sandblasting or chemical treatments must be carefully controlled to avoid damaging the substrate.

- Adhesion:The effectiveness of a coating often lies in its ability to stick. Ensuring the surface is conducive to adhesion requires meticulous chemical or physical preparation.

- Environmental Concerns:Pre-treatment processes can involve hazardous chemicals. Managing these substances without harming the environment or breaching regulations is a significant challenge.

Application Process Challenges.

The application process, a pivotal stage in coating operations, embodies a unique set of challenges across various methods. Each technique, from the meticulous brushwork to the precise science of electrophoretic deposition, demands a tailored approach to overcome its inherent hurdles.

- Brushing Challenges–

Skill Dependence: The quality of a brushed finish heavily relies on the operator’s technique, making consistency hard to achieve across large or multiple projects.

Time-Consuming: Brushing is labor-intensive and slow, making it less suitable for large-scale or time-sensitive projects.

- Spraying Challenges–

Overspray: A significant portion of paint can miss the target, leading to wasted material and environmental concerns.

Equipment Precision: Achieving uniform coverage requires finely tuned equipment and skilled operators to manage variables like air pressure and paint viscosity.

- Dipping Challenges–

Thickness Control: Ensuring an even coat, particularly on complex shapes, can be challenging as the thickness can vary depending on the withdrawal speed.

Waste Management: Excess paint needs to be managed efficiently to prevent waste and ensure cost-effectiveness.

- Roller Coating Challenges–

Limited to Flat Surfaces: Roller coating is most effective on flat surfaces, reducing its applicability for objects with complex geometries.

Inconsistencies: Variations in pressure and speed can lead to uneven application and thickness.

- Flow Coating Challenges–

Control Over Flow: Maintaining a consistent flow of paint over the surface requires precision to avoid sagging or uneven thickness.

Waste: Similar to dipping, managing excess material efficiently is crucial for environmental and cost considerations.

- Spin Coating Challenges–

Centrifugal Precision: Achieving a uniform film thickness depends on the precise control of the spinning speed and duration.

Material Limitations: The method is typically limited to relatively small and flat substrates due to centrifugal forces.

- Electrophoretic Coating Challenges–

Electrical Parameters: Uniformity and thickness control are critical. The process also demands a deep understanding of the electrical parameters to ensure even deposition across complex geometries.

Equipment Complexity: The need for specialized equipment and understanding of electrochemical processes adds a layer of complexity and cost.

In tackling these application challenges, innovation and expertise in coating technology play crucial roles. The quest for efficiency, quality, and sustainability drives continuous improvement in equipment, materials, and techniques. By understanding and addressing these application-specific hurdles, the coating industry can deliver superior finishes that meet diverse project requirements and withstand the rigors of their intended environments.

Drying & Curing Post-Treatment Challenges.

Once applied, the journey isn’t over. The drying and curing phase is vital for the coating’s final properties and performance:

- Time and Energy:Efficiently curing coatings without compromising quality requires optimizing time and energy use, particularly for methods needing high temperatures or UV light.

- Environmental Control:Conditions such as humidity, temperature, and airflow must be tightly controlled to prevent defects.

- Compatibility:Some coatings require specific curing methods, which may not be compatible with all substrates or project scales.

Across all these stages, the overarching challenge remains balancing cost, efficiency, and environmental impact with the need for a high-quality finish that meets the project’s requirements. As coating technologies evolve, so too do the solutions to these challenges, leading to innovations in materials, application equipment, and environmental controls. By understanding and addressing these technical hurdles, we can ensure that our projects not.

How to Choose the Best Coating Application Method for Your Project?

Are you faced with the daunting task of choosing the right paint application method for your project? The decision-making process can be overwhelming with various factors to consider, such as coating type, substrate material and desired finish. However, have no fear! In this guide, we’ll break down the key considerations and provide you with valuable insights to help you make an informed decision. After reading this chapter, you will have the knowledge to choose the best coating application method for your specific needs.

- Coating Type:Different coating types require specific application methods. Certain coatings may be better suited to spraying, while others may require brushing or dipping. For example, spray coating is commonly used for paints, while dip coating is suitable for some industrial coatings. Consider the paint’s viscosity, drying time, and curing requirements. The type of coating you use will greatly affect the application method.

- Substrate material:Consider the material of the surface you want to coat. Certain application methods may be more compatible with certain materials. For example, for metal surfaces, spray painting is often preferred, while for wood, brushing may be better. Ensuring compatibility between the coating and the substrate is critical.

- Size and shape of object:The size and shape of the object being coated will also influence the choice of application method. Large, flat surfaces may benefit from spraying, while complex shapes may require brush or roller application. While smaller, detailed objects may be better suited to flow coating or dipping.

- Required finish:Your expectations for the project will also affect the application method. Such as smooth, textured, glossy or matte, will determine the best application method. For a smooth, even finish, spraying may be your best option. However, if you are looking for a textured finish, roller coating or flow coating may be more suitable.

- Desired Function:Consider the desired function of the coating, such as corrosion resistance, UV protection, or chemical resistance. Certain application methods may be more suitable for achieving these functions. For example: electrophoretic coating has stronger corrosion resistance than ordinary spraying and brushing.

- Application environment:The application environment of the coating should also be considered. Temperature, humidity and ventilation will influence the choice of method. But for outdoor applications, spraying may be preferable to ensure even coverage and quick drying.

Each of these methods has its advantages and disadvantages as we conclude our exploration of paint application methods. Remember, the right approach can have a significant impact on the success of your project. By considering factors such as coating type, substrate material and environmental conditions, you can ensure the best results. We hope this guide helps you make informed decisions and achieve excellent results on your paint projects. For more information and resources, don’t forget to browse our directory of reliable coating suppliers on our website.